Electric wrenches are among the tools that have changed human labour the most. With their ideal balance of portability, accuracy, and efficiency, these little yet effective instruments have become essential for experts and do-it-yourselfers. Electric wrenches can revolutionise your productivity and workflow, regardless of the task you’re performing—automotive repairs, building projects, or complex assembly.

Superior Strength and Acceleration

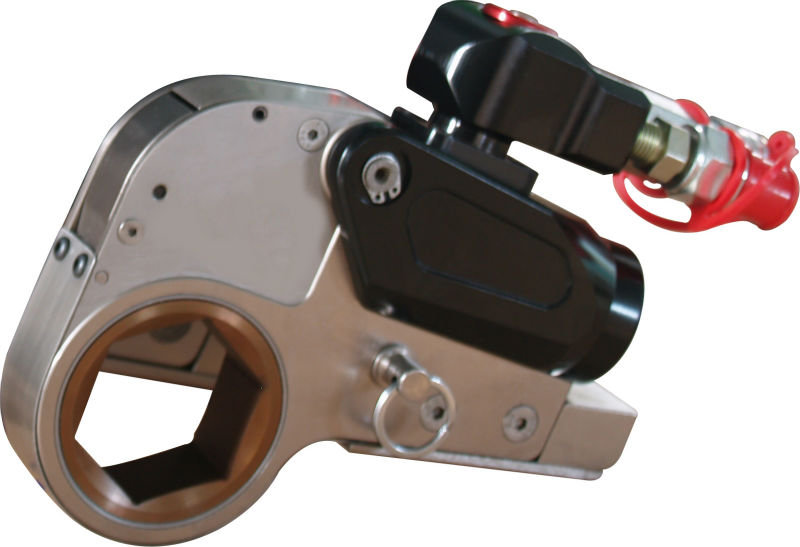

Electric wrenches’ remarkable torque and power generation within a small, ergonomic package is one of their main benefits. Even the most difficult nuts and bolts are easy to work with thanks to these cutting-edge devices, which use electricity instead of traditional hand tools to produce precise and consistent torque output.Envision can adjust fasteners that would typically need a great deal of physical exertion or specific instruments.

Higher Productivity and Efficiency

Electric wrenches may greatly increase your productivity and efficiency in any trade or profession where time is money. With these technologies, you can do more tasks in less time, which boosts productivity and profitability by doing away with the need for physical labour and lowering the possibility of injury.

The ability to be flexible and agile

Powerful and adaptable, electric wrenches are helpful instruments for a multitude of tasks. These multipurpose instruments can be used for almost any kind of operation that involves nuts, bolts, and fasteners, from construction sites to automobile repair shops, and assembly lines to home DIY projects.

You can handle fasteners of different sizes and configurations with the assortment of sockets and accessories that many electric wrenches come with. Specific versions also have torque settings that can be adjusted, allowing you to customise the output to meet the unique needs of each task and guarantee maximum efficiency and safety.

Lower Risk and Increased Safety

Hand tools that are not made with modern safety features put you at risk for slips, falls, and injuries from repetitive strain. The danger of these injuries is reduce and a safer working environment is produce by the ergonomics and safety considerations that went into the design of electric wrenches.

Use Cases and Apps

An indispensable item for any toolbox, electric wrenches are use extensively in a wide range of sectors and professions. A few instances of how these potent instruments excel are as follows:

Automobile Maintenance and Repair

In the automobile sector, electric wrenches are neede for jobs like wheel removal and installation, maintaining suspension parts, and working on engine assembly. They can reduce the risk of breakdowns and guarantee vehicle safety by precisely delivering torque output to ensure that crucial components are tightene or loosene.

Assembly and Construction

Electric wrenches are essential for ensuring accurate and safe fastener placement in everything from complex machinery assembly to large-scale construction projects. Heavy machinery assembly, fixture and fitting installation, and bolt tightening are just a few of the jobs that their strength and adaptability make them perfect for.

Industrial upkeep and fixing

Electric wrenches are indispensable instruments for effective maintenance and repair procedures in industrial environments where downtime can be expensive. Technician productivity is increase and equipment downtime is reduce when they can precisely and swiftly remove and tighten screws.

Do-it-yourself projects and home renovation

Electric wrenches can alter more, even for ardent do-it-yourselfers and home repair enthusiasts. These instruments offer the strength and accuracy needed to handle various jobs with ease, from putting together furniture and playground equipment to carrying out regular maintenance.

Conclusion:

Electric wrenches are a better option than traditional hand tools like electric wrench tool, increasing productivity, safety, and efficiency while producing dependable and consistent results in a variety of contexts, including industrial settings, home improvement projects, and automobile repair shops. We may anticipate even more sophisticated and powerful electric wrenches to come into existence as technology develops, which will increase our capacity to precisely and easily complete even the trickiest fastening jobs.